- Posts

- Renewable heat

Solar trackers: useful for PV, even more so for solar thermal!

Hugues DefrevilleWhat is the purpose of solar trackers?

Today we are focusing on solar trackers, or “sun tracking systems“.

The use of these systems has developed very strongly over the last ten years in the photovoltaic (PV) sector (for electricity production) [1]. For solar thermal, they were until recently only used for so-called “concentrating solar power” technologies, of which they are a necessary and essential component [2]

A few years ago, we had the idea of testing them for the orientation of large flat-plate solar thermal collector fields. This work was concluded with the filing of our first patent and the realisation of two innovative projects, unique in the world!

Want to know the whole story? Discover it in this new article (and exciting) article 😎 !

What is a solar tracker?

A solar tracker is a mechanical system that aims (as its name indicates) to follow the path of the sun throughout the day thanks to a motorization and a transmission system of the movement.

It behaves in the same way as sunflowers: throughout the day, the structure rotates to capture as much sunlight as possible.

No need to be an energy specialist to understand the interest of this device: it optimises the capture of the sun’s rays by the solar panel, whether it is thermal or photovoltaic, and thus increases its productivity for a given surface.

For solar thermal, these trackers can have other interests, let’s discover them !

One tracker, how many axes?

Although there are many different types of solar trackers, they can be grouped into two main groups: single-axis trackers and dual axis trackers.

- Single-axis trackers have only one degree of freedom. They are generally aligned on a North-South meridian, and follow the sun’s path from the East (in the morning) to the West (at the end of the day). This is known as “azimuth” tracking and optimises the orientation of the sensors.

- Dual axis trackers can follow the sun more precisely, in 2 degrees of freedom: they can adjust according to the azimuth (optimising the orientation of the collector) and the elevation of the sun (optimising the inclination of the collector) and thus really optimise the sunlight received throughout the day. They allow a much higher productivity, their implementation cost is also much higher.

Trackers for solar photovoltaics: advantages and disadvantages

The aim of a tracker for a solar photovoltaic system is to increase its productivity, without increasing its price too much.

Here are some figures:

- With a single-axis solar tracker, the yield is 10% to 20% higher than with a conventional south-facing installation.

- With dual-axis trackers, the yield is up to 30% higher. The cost of installation increases in a way that is relatively correlated to the increase in efficiency compared to a fixed installation. As an order of magnitude, the price can increase by 10 to 15% for single-axis trackers and up to 50% for dual-axis trackers, depending on the specific constraints of the project.

Note that trackers also require more regular maintenance.

Just a few years ago, when photovoltaic modules were very expensive (compared to today), trackers were particularly profitable, as they allowed the use of this “expensive” production equipment to be optimised. But as panels have become cheaper (10-fold reduction in price per Wp in 15 years), the profitability of sun tracking has largely decreased

However, the use of a tracking system may have other interests:

-

- In case of limited land availability (higher energy production per used land area),

- For installations that are not connected to the public electricity grid, where the high morning and end-of-day production generated by trackers is often better suited to the consumption profile of the sites (in a home, a lot of electricity is consumed in the morning and evening). Thus, the tracker makes it possible to reduce the need for costly energy storage such as batteries.

Trackers for solar thermal systems

These are suitable for different concentrating technologies, as well as for flat plate collectors!

For concentrated solar thermal technologies :

As you may have discovered in our dedicated article, tracker systems are used in all so-called “concentrating solar thermal” technologies.

In this case, trackers are used to orient mirrors that reflect and concentrate the sun’s rays onto a receiver/concentrator:

- Single-axis trackers allowing concentration on a tube (linear concentrators such as parabolic troughs or linear Fresnel mirrors)

- Dual-axis trackers allowing concentration on a specific point (point concentration such as parabolic discs or tower power plants)

Single axis tracker

Dual axis tracker

With these technologies, trackers are absolutely necessary for geometrical reasons: the position of the mirrors must be very precise because, due to the geometrical effect, even a small shift would defocus all of the sun’s rays and quickly reduce all thermal energy production to zero.

What about flat plate solar thermal collectors?

Given the growth and interest in trackers for large utility-scale photovoltaic installations, we have studied their application to large solar thermal collector fields in order to optimise their production.

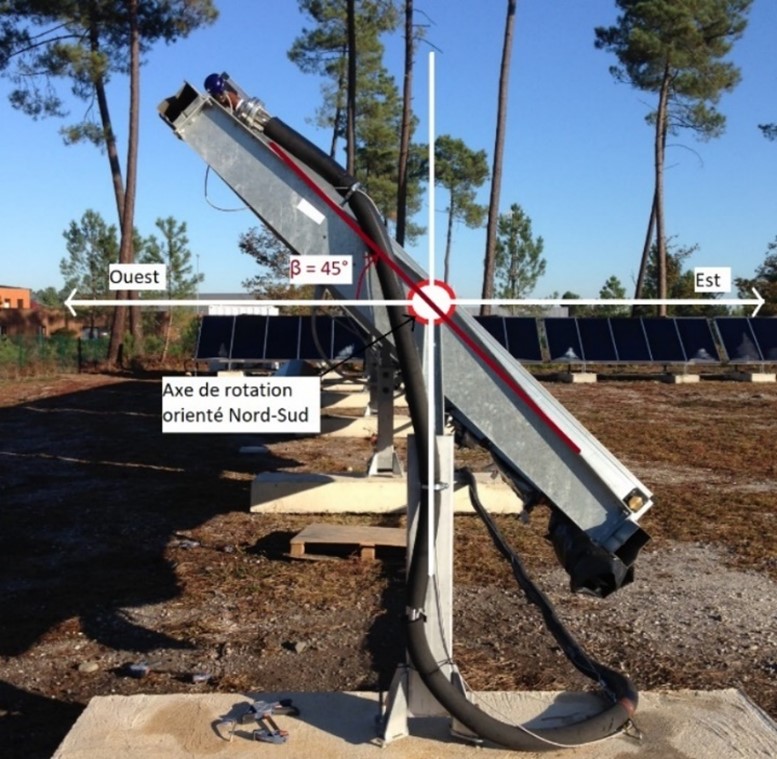

The use of single-axis trackers appeared to be the best option:

![]()

- This is the main technology used in large photovoltaic solar fields,

- Technically, they are more suitable for solar thermal, which requires piping to carry the heat transfer fluid. They have greater flexibility constraints than electric cables: a single-axis system reduces the use of hydraulic hoses and allows them to “work” on a single axis of freedom, a necessary condition for their mechanical resistance over time!

Thus in 2016, we decided to integrate in one of our R&D programmes (OPTISHIP programme to be discovered at this link) the realisation of a test bench (installed on the field of our partner Arcelor Mittal Exosun) in order to study in detail this solution and prepare its implementation on a larger scale.

This work has allowed us to draw clear conclusions on the interest of these trackers for solar thermal!

- Productivity improvement: of course, the first interest is to increase the productivity of a solar thermal collector of a given surface: it thus captures much more solar radiation and allows to produce more heat than an installation with fixed collectors.

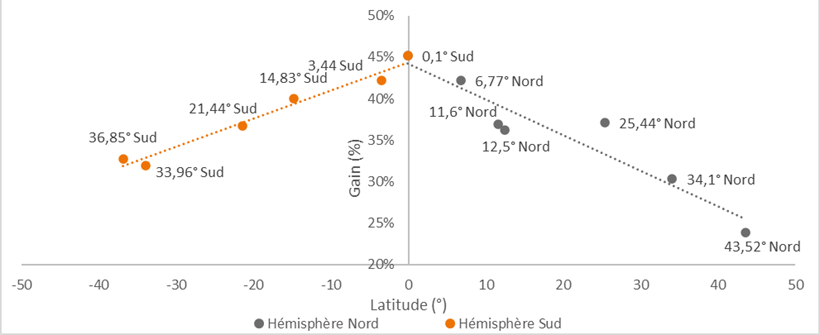

- This gain in production will depend on the geographical location of the installation and in particular on its latitude: as you can see in the graph below, this gain evolves globally between +45% (projects closest to the equator) and +20% (for projects located in the typical latitudes encountered in France).

Please note that this production gain also depends on the temperature of the targeted heat supply as well as on the “brightness index” of the targeted geographical area (the brightness index measures the share of direct and diffuse solar radiation, i.e. the overall “cloudiness” of a region).

Variation of delivered energy gain with latitude

- Improved reliability and lower management costs: Another very important advantage of the tracker for large-scale solar thermal is its ability to enable ‘overheating’ management.

What is “solar thermal overheating“?

Unlike a conventional boiler, a conventional solar thermal system cannot “stop” its production on demand, for example if there is no more energy consumption on the user side. The solar thermal collectors remain under the sun’s rays and will therefore continue to rise in temperature: this is what is known as an “overheating” phenomenon.

The heat transfer fluid in the collectors will then rise in pressure, and to avoid damaging the equipment, a safety system equipped with a valve will trigger the draining of the entire installation to prevent the pressure from rising too high. On the scale of a large power plant, such an event leads to significant delays and costs for restoring fluid to the circuit and restarting the installation (several days of production losses). Different systems for managing overheating exist but have disadvantages or limitations: of course, a large heat storage system can be designed (this is always the case in our installations), but it has a significant cost, and in the event of an untimely shutdown over a long period (for example, a “machine breakdown” at an industrial site), this storage may not be sufficient.

In this case, an air heater can be used to evacuate the heat produced into the open air. In practice, this involves the use of fans that discharge the energy produced into the outside air, which means that electricity is consumed, which also has a significant cost…

The solar tracker makes it possible to get rid of these systems in part by “de-tracking” or “defocusing” the collectors in relation to the sun when there is no longer a need for heat. This makes it possible to considerably reduce the power produced and thus avoid the phenomenon of overheating, even if there is no heat consumption for a certain period of time and the thermal stores are “full”.

- Improved flexibility and adaptability to our customers’ needs: in addition to the previous use, and in a more refined way, the tracker can be used to modulate the power produced by the plant according to the user’s energy consumption. Therefore, if the user consumes a certain amount of power (in MW), the sensors will position themselves in a certain position to produce only the necessary power. This greatly reduces or eliminates the need for an energy storage system [3].

Although the principle is simple, the implementation is relatively complex, with issues of thermal inertia and relatively complex regulation/control to achieve real flexibility in our plants. In fact, it is on this aspect of “power regulation by single-axis tracker” that we filed our first patent!

- Reduction of the required storage volume: Another specificity is the modification of the production profile of the solar installation, which can be better adapted to certain consumption profiles. Depending on the position of the collectors during the day, the midday production peak is “limited” and the production is smoothed out over the day. This production curve is better adapted to certain consumers and reduces the need for storage systems.

![]()

Comparison of a fixed daily production curve vs tracker

![]()

Annual evolution of tracker vs. fixed production gain

This is also true for the annual production profile of the solar power plant. Compared to a fixed installation facing south, more energy will be produced in summer, but a little less in winter.

These results confirmed the interest in integrating these systems into some of our projects!

Given their higher cost, the use of trackers remains a choice to be modulated per project by our engineering teams.

Newheat has already built 2 solar thermal power plants equipped with trackers

- CONDATSOL supplying the Condat paper mill – LECTA group

- EMASOL supplying the district heating network of the town of PONS.

Many other projects are under development!

Discover the articles mentioned:

[1] Need to know more about solar thermal and solar photovoltaic? We have an article on this topic!

[2] No worries, we also have an article on the different types of solar thermal collectors

[3] Check our article on thermal energy storage