- Posts

- Non classé

Dynamic modelling and renewable heat

Hugues Defreville

What is dynamic modelling?

It is a process by which the representation of a complex system (physical system or concept) is established, in order to study and measure changes or variations in certain elements or key parameters.

Dynamic energy system models

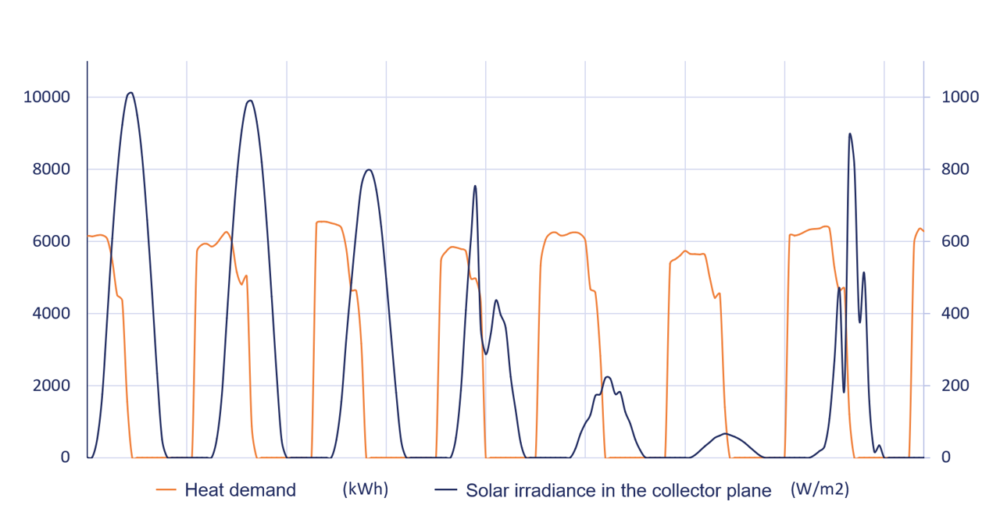

Renewable heat production systems are dynamic systems (you can consult our article dedicated to this form of energy here). The high variability of the solar resource, coupled with the variability of heat demand, means that a dynamic modelling approach is necessary, which is more accurate than a static approach, but also more complex. This is particularly necessary for components with significant thermal inertia (solar array, piping, storage, etc.).

Dynamic models are so called because they describe how the properties of the system change over time, and often use differential equations. Some of these equations have no analytical solution and therefore require a numerical solution that approaches the exact solution at regular intervals. The continuous variables of the real system are then evaluated discretely by the simulation, i.e. for a finite number of instants. Static and quasi-static models, on the other hand, consider a system in steady state, whose variables do not depend on previous instants.

Once the digital models have been developed (i.e. specified, programmed, tested, etc.), they are then used by software to perform calculations to predict or evaluate the performance of the systems represented. If these calculations describe the evolution of the system over time, we speak of dynamic simulation.

Sunshine/heat demand curves for an industrial process over seven consecutive days

Magnitudes and phenomena to be represented

To accurately represent the performance of renewable heat production systems, it is necessary to be able to predict heat flows, flow rates, pressures and temperatures of heat transfer fluids, as well as auxiliary consumption (pumps, trackers, cooling systems, etc.) throughout the year.

The main phenomena governing renewable heat production plants are related to thermal engineering (mass and energy balances) and hydraulics (head loss calculations, pump performance). Geometric and optical relationships are also used to estimate the solar energy incident on the collectors on the basis of the available solar resource and the configuration of the solar field.

What is dynamic modelling used for?

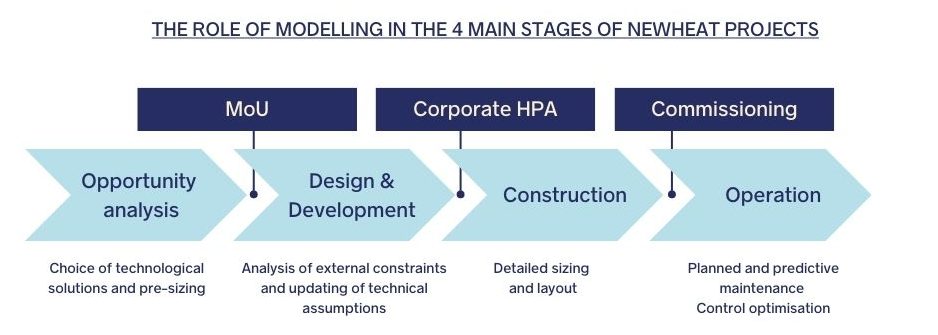

Modelling is useful at every stage of a renewable heat project

Modelling is needed at all stages of project development

- Opportunity

- Design / Detailed engineering

- Operation (to optimise plant operation through fault detection and diagnosis)

Here are its main uses :

- Estimating the performance of a given configuration: in addition to annual heat production, modelling tools can be used to estimate numerous technical and economic indicators for the installation (e.g. overheating rate, cost of heat, etc.).

- Parametric studies: to size the various components of an installation (solar array size, storage volume, heat pump power, etc.)

- Comparision of detailed engineering designs: creation of solar sub-fields according to terrain constraints, characteristics of integration points in the customer process, choice of control system, etc.

- In operation plants’ performance studies: identification of under-performance, optimisation of plant operation, etc.

At Newheat, in addition to its tasks related to the needs listed above, the modelling team supports the company and is constantly adapting to meet the needs of the development and operational teams.

Multi-source renewable heat production facilities: new concepts, new challenges

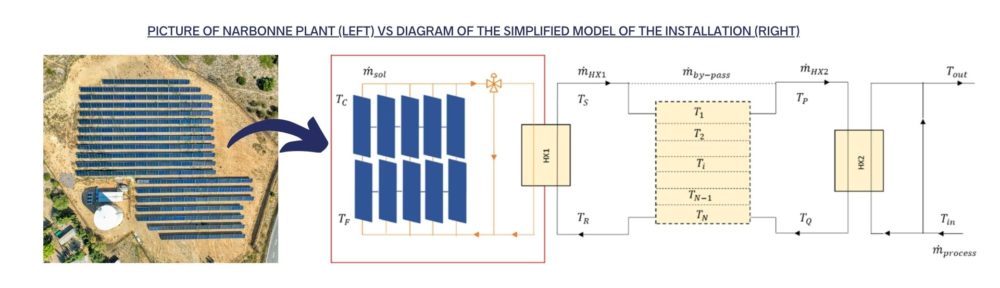

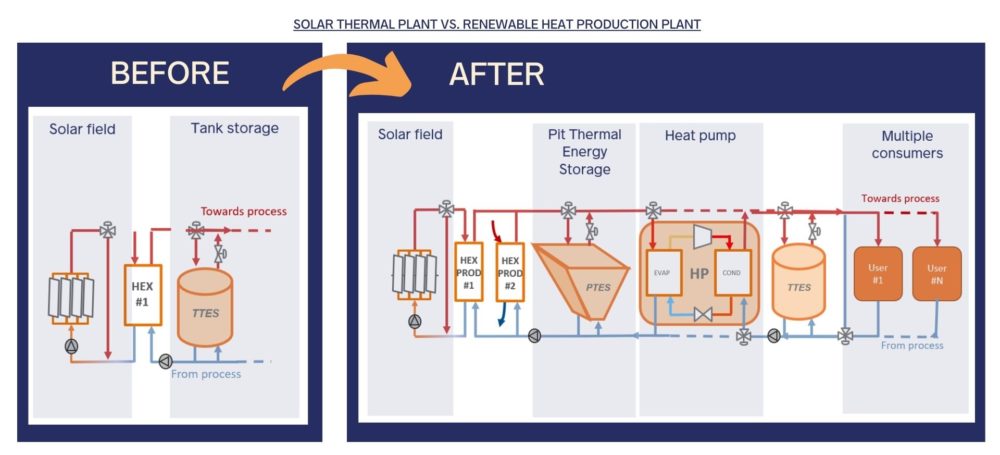

For several years now, Newheat has been designing, building and operating solar thermal power plants with storage. Faced with the need to increase the share of renewable energy in the energy mix, it is essential to offer heat production systems that multiply the sources of renewable heat and its integration points. To design, build and operate these complex installations, Newheat has developed modelling tools capable of accurately representing :

- New components: heat pumps, biomass boilers, recovery heat exchangers, seasonal storage systems such as pit storage or geothermal probes, non-solar producers, etc.

- New control methods: arbitration between producers, between producers and storage, between consumers….:

Dynamic modelling at Newheat

Since the very beginnings of the company, modelling activities have been at the heart of Newheat’s expertise, built on an ambitious R&D strategy and a strong technical DNA.

These activities have led to the in-house development of tools at the cutting edge of the industry, adapted to all stages of a renewable heat production plant project: from the screening of plant architectures adapted to a wide variety of needs, to the development of digital twins of existing installations or in the detailed engineering phase.

These modelling activities are based on a development process based on the best IT tool development standards, in order to guarantee the robustness, reliability and versatility of the models.

These activities benefit from collaboration with a wide range of partners (software developers, control specialists, technology suppliers, international researchers, etc.) through Newheat’s participation in expert committees (International Energy Agency tasks) and standardisation committees. These activities are also widely supported at national level by ADEME, notably through the Scale&Mix ( (2018-2021) and Thermodeep (winner of the i-Nov competition, 2021-2024) programmes.

Find out more about the Modelling team by watching the video interview with our scientific leader here.

Need more information about dynamic modelling of renewable energy production systems? Our team of experts is available to answer your questions!