- Posts

- Storage

Solar thermal and heat storage for District Heating

Hugues Defreville

District heating to decarbonise our cities

After enjoying reading our articles on renewable heat, how solar thermal energy works and how to store it…it’s time to look at the different users!

Our projects are aimed at large heat consumers, such as industrial sites that use heat in their processes…or cities that need to heat a group of buildings or homes. Today, we focus on one of the leading solutions for decarbonising heat in cities: district heating or district heating networks! As you will see, district heating and solar thermal energy make a very good match!

What is a district heating network (DHN) ?

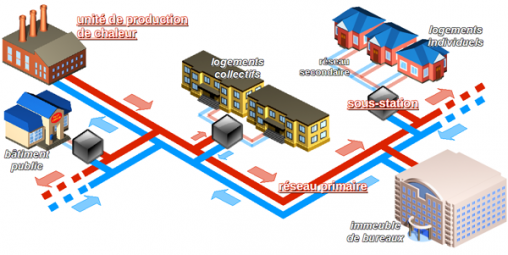

A DHN is a distribution network that delivers heat in the form of water or steam from one or more heat generating facilities to delivery points in the technical rooms of individual buildings.

This allows for :

- heating,

- the production of domestic hot water (DHW),

- or specific uses (e.g. heating of swimming pools).

The buildings served are residential, tertiary, industrial, public facilities … all can be connected to a DHN!

The principle of a heating network is therefore based on the mutualisation of heat production resources for several clients/buildings at the scale of a territory (district, town, etc.).

This method promotes the use of renewable and local energies for heat production (waste heat, solar thermal energy, geothermal energy, biomass, biogas, etc.) because of their high investment costs.

French Ministry of Ecological Transition and Territorial Cohesion

Heat network scheme, source: Ministry of Energy Transition

Heat networks, which actors involved ?

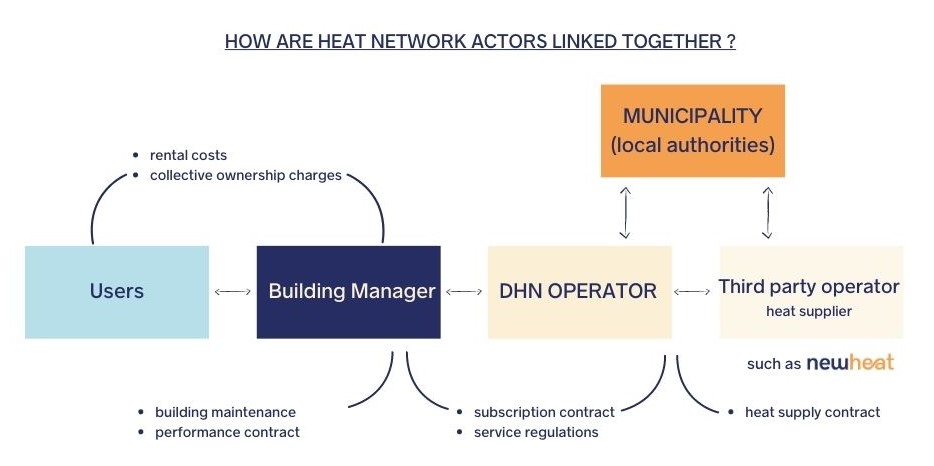

In most cases, a district heating network is created by local authorities: metropolis, community of municipalities, town, mixed syndicate (however, this competence is not exclusive to the authorities, district heating networks can be created by private actors). As soon as the local authority exercises this competence, the activity of production, distribution and delivery of heat falls within the framework of a public heating service, which implies the following obligations for the latter

- equal treatment of users,

- control of the service, regardless of the management method chosen,

- guarantee of the continuity of the public service.

In the event of a public service heating network, the degree of outsourcing of the service to a possible operator will depend on the management method chosen by the local authority:

- for an internalised public service, the local authority is responsible for the financing, design, operation, maintenance and marketing of the service; the local authority is thus the operator,

- for an outsourced system, the operation and maintenance of the network is carried out by a private operator. An operating contract binds the local authority to the operator. The duration of an operating contract is several years,

- for a concession, the “concessionary” operator is responsible for financing, designing, operating, maintaining and marketing the service. A concession contract contractually links the local authority to the operator. In practice, a concession contract very often exceeds 15 years.

In fact, the larger the network, the greater the transfer of the service to a private operator. This transfer is motivated by the outsourcing of marketing and operating risks, the desire to benefit from the industrial know-how of operators in complex operations and their ability to mobilise financing, etc. Thus the concession management method represents 36% of the number of heating networks in France but 73% of the total heat delivered by them.

The end customer is a “subscriber” of the district heating network, and holds a subscription contract that binds him contractually to the local authority or to the operator when the service is concessioned. The building manager is the final customer, sometimes distinct from the final user; for example, in a condominium, the subscriber is the condominium association and the final user is the occupant of the dwelling.

For exemple, in France, the operation and management of DHN is is mainly carried out by four major operators: Engie Services, Dalkia, Coriance and Idex. These operators held more than 90% of the market in 2019.[1]

Third party operators are also likely to intervene in the sole production of energy with a view to delivering all or part of it to a heating network. This is the case of owners of assets generating waste heat (such as household waste incineration plants or data centres, for example) or, like Newheat, independent renewable heat producers. In both cases, these third parties remain distinct from the heating network operator and enter into heat supply agreements with the latter for periods of around 15 to 30 years.

Solar thermal, a significant potential component of the DHN’s energy mix

Unlike common belief, the impact of the geographical location of the equipment remains relatively limited (for example, Denmark is the champion of solar thermal on district heating networks). The implementation of solar thermal on DHN is therefore quite feasible whatever the latitude considered [2].

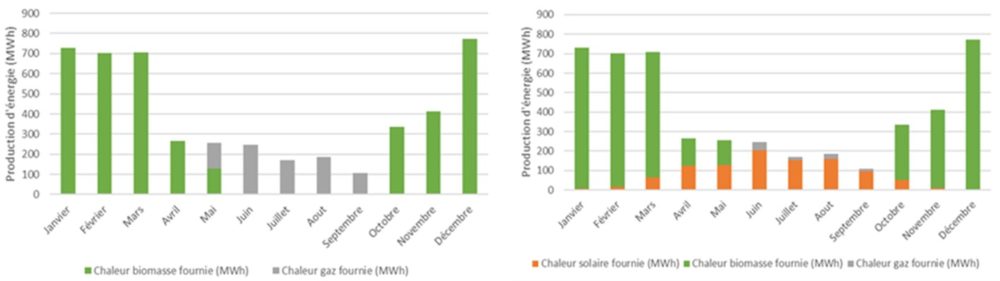

However, it should be remembered, and this makes sense, that solar thermal provides the most energy… when solar radiation is at its maximum, i.e. in summer!

Thus, for DHN, large solar thermal installations (several MWth) cover summer consumption, which generally corresponds to DHW needs from May-June to August-September, depending on the geographical location (also called “summer heel”), in relay of other installations used in winter. The use of this technology then replaces fossil energy consumption when, for example, biomass plants are shut down (due to their technical minimum) or when other renewable production means are not available to cover this backlog.

The network can thus be supplied for 3 to 5 months of the year with 100% renewable energy and without any emissions (CO2, fine particles…): solar thermal. Of course, solar thermal plants can still supply heat to the district heating in winter and mid-season.

Over these time frames, the thermal energy can :

- either be delivered directly to the network’s set temperature in “heating mode” (as is the case for our Narbosol plant connected to the city of Narbonne’s heating network),

- or be used in “pre-heating mode” to raise the return temperature of the DHN (as is the case for our Emasol plant connected to the City of Pons’ heating network).

Narbonne’sDistrict Heating Network energy mix before and after the implementation of Newheat solar thermal plant

Regardless of the configuration chosen for the integration of the solar thermal plant into the heating network, a “daily” storage tank is systematically associated in order to compensate for the time lag between solar production (during the day only) and consumption on the district heating (including at night), and in order to manage any risk of overheating the system. This tank, which can have a capacity of several thousand m3 , can cover the needs of the network for several days(check our article).

Ultimately, a solar thermal plant combined with daily storage can generally cover between 15 and 20% of the heat needs of a DHN.

An ideal technological solution for innovative and virtuous district heating

While the amount of sunshine obviously plays a role in solar production, other variables such as the consumption profile and the grid temperature regime have a strong influence on the performance of the solar thermal plant.

Lowering the grid return temperature improves the average collector efficiency and maximises the use of solar energy. By lowering the temperature regime by 10°C, an additional 10 to 20% of solar production can be achieved. At constant size, the solar thermal plant and its storage will deliver more renewable heat (or at constant production, the land area of the installations will be reduced!).

On the other hand, lowering the temperature is also virtuous for the network itself as it reduces heat losses in the distribution network and diversifies the sources of renewable energy and energy recovery (by using other low temperature heat sources). This contributes to improving the overall energy efficiency of the heating network, and consequently, the price of heat for the subscribers.

Newheat solar thermal plant and biomass heating plant for the City of Pons (France) DHN. Credits: ADEME x Magenta Films

In addition to the creation of completely decarbonised and combustion-free energy, these solar thermal plants can also provide a very interesting storage service for the heating network. Indeed, it is usually possible to make the storage tank of the solar field available to the other production means of the DHN. Thus, in winter and mid-season, when the tank is little or not solicited by the solar field, it can be used to store the renewable energy produced by the heating plant of the district heating operator, as is the case with our storage tank in Pons (France), made available to the biomass heating plant of the network operator. This gives the operator more flexibility, and allows even more gas to be removed during peak consumption full stops, improving the network’s renewable energy rate and, once again, the price of heat for the customer.

Similarly, the inter-seasonal storage systems presented in our previous article, whether or not associated with solar thermal plants, also provide numerous services to heating networks. Shared with the network’s other production resources, these solutions make it possible to :

- significantly increase the renewable energy rate of the district heating (up to 100%) without necessarily creating an additional production unit,

- provide flexibility in the management of heat distribution,

- generate a high degree of flexibility in the management of the installations,

- optimise the performance of existing production facilities.

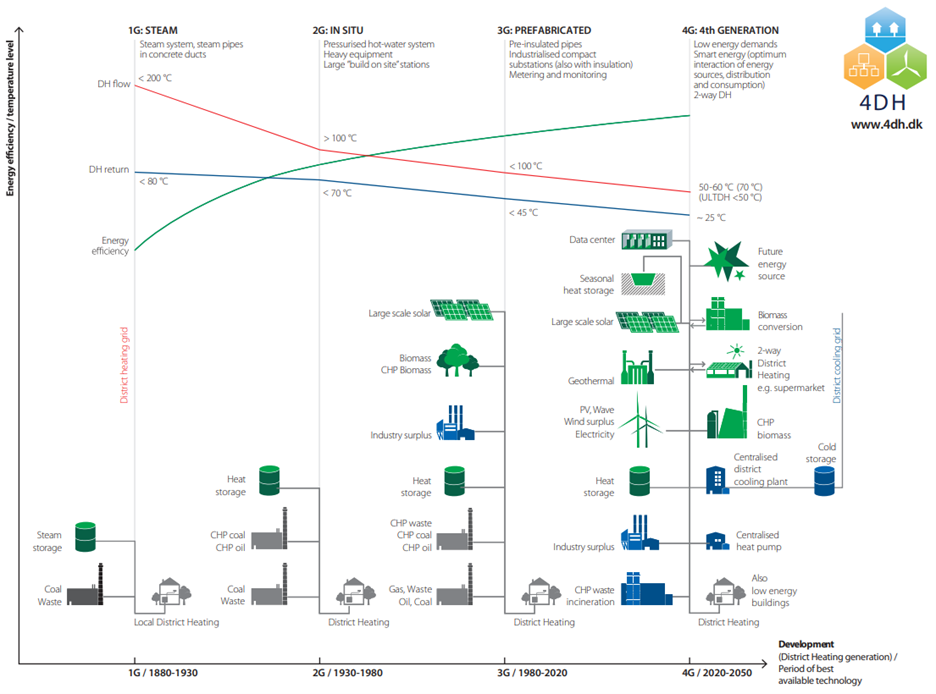

These plants, coupled with daily or inter-seasonal storage infrastructures, are at the heart of discussions on the most recent so-called “4th generation” networks, operated at low temperature, massively exploiting the potential of local renewable energies and relying on thermal storage to optimise interactions between the various energy vectors.

The following graph presents the technical evolution of district heating networks from the creation of their concept at the end of the 19th century to these new “4th generation” networks:

District heating technological evolution (source : “Progression of District Heating-1st to 4th generation”,J. E. Thorsen et al., 2018)

Economic interest for local authorities

Our clients have already noticed that the addition of a solar thermal solution to their district heating network stabilises the end-users bill.

We’ll tell you why!

Solar heat prices are largely based on a stable component: as the solar resource is free and unlimited, the plant operates without any fuel purchases, completely independent of the energy market! Therefore, the indexation of the variable solar heat price is based on the cost of labour (covering the operating costs).

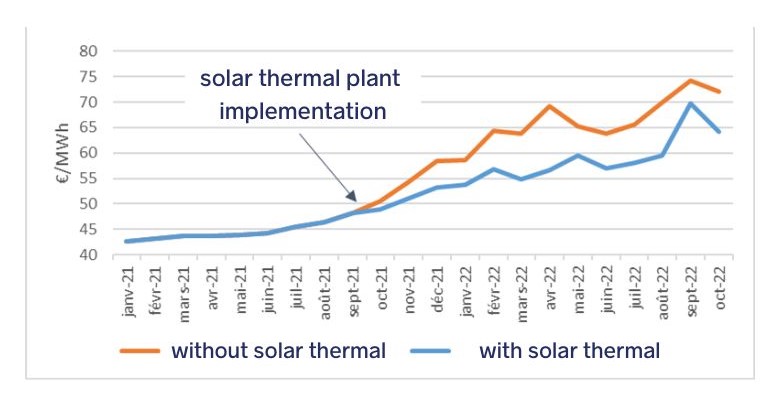

To illustrate the stability of the heat prices of the district heating networks integrating solar energy in their energy mix (and thus in their tariff component), the graph below compares the variable part of the energy bill of the Pons network with and without solar heat import. This graph represents the evolution of the energy bill, as it would have evolved without the solar heat import implemented by Newheat in September 2021 (in orange) compared to the real situation, including solar thermal from this date (in blue).

By substituting solar energy for gas and biomass, the Newheat solar thermal plant has made it possible to save more than 7 €/MWh on average over the first year of operation, and this difference is set to increase over time due to the inflationary trend in energy prices!

Heat price comparison at the Pons district heating network with and without solar heat imports (source: Dalkia, operator of the Pons district heating network)

When the heat supply contract expires, the solar thermal plant and its storage can, depending on the wishes of the municipality

– either be recovered by the latter in exchange for payment of a sum corresponding to the terminal value of the installation. The municipality can then have access to very competitive energy (only the operating and maintenance costs remain to be covered) for many years to come (the lifespan of solar thermal plants exceeds 30 years)

– or be completely dismantled by Newheat, which ensures the restoration of the land. It should be noted that almost all of the materials used in the plant are recyclable and recycled at the end of their life.

[1] Source Ademe – etat des lieux de la filière réseaux de chaleur et froid de mai 2019

[2] « Solutions techniques pour optimiser les réseaux de chaleur dans un contexte de développement de bâtiments basse consommation », AMORCE et Inddigo, 2011