- Posts

- Thermique

Towards more competitive and resilient market gardens thanks to renewable heat

Pierre Delmas

French greenhouses producing vegetables and fruits face a major challenge: controlling their energy costs in a context of volatile gas and propane prices and international competition, while maintaining climatic conditions that guarantee sufficient productivity.

For many, heating accounts for nearly half of the production costs, which directly affects yields. Securing the supply of heat is therefore an essential lever for competitiveness and survival. Renewable heat offers a concrete solution that is both economical and sustainable, strengthening the sector’s autonomy.

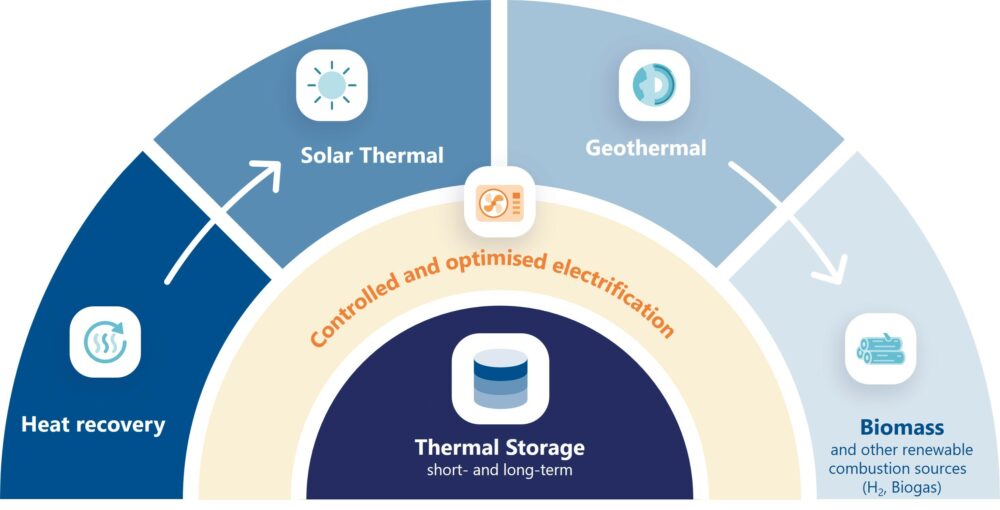

This is precisely where Newheat comes in: we support greenhouses that produce vegetables in securing their production and control management of their heating costs, while decarbonising. We design and operate multi-source systems (heat recovery, solar thermal, thermal storage, heat pumps, electric boilers, etc.) that are intelligently controlled to deliver heat at the best cost according to the greenhouse settings, weather conditions and energy markets (gas, electricity, etc.).

This approach ensures the reliability and competitiveness of the production while reducing the dependence on fossil fuels and accelerating the transition to more autonomous models.

The energy needs of greenhouses used for market gardening

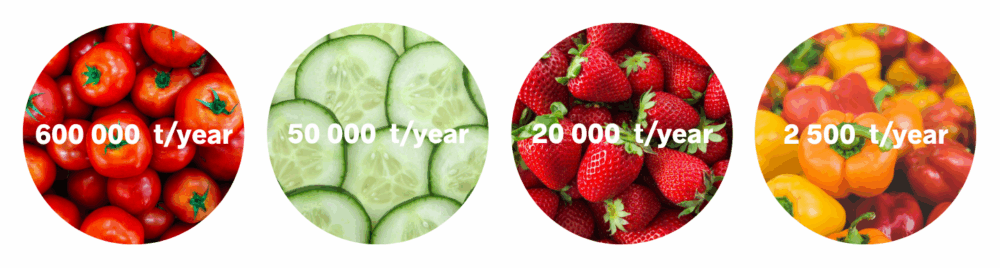

Greenhouses allow fruit and vegetables to be produced all year round: tomatoes, strawberries, cucumbers, vanilla and peppers, which require heat and light, through meticulous control of the climatic conditions.

These glass or plastic greenhouses recreate a controlled microclimate that is favourable for the crops growth, ensuring consistent production yields. Whether they are polytunnels, closed or semi-closed greenhouses, ranging from a few square metres to several hectares, they make the most of solar radiation and allow to precisely control of conditions that impact the growth of the crops : temperature, light, humidity, CO2 concentration, etc.

Thermal balance at the heart of performance

The productivity of these greenhouses depends heavily on the availability of competitive heat at the right temperature. Heating serves two main purposes:

- To prevent excessive humidity (risk of disease), especially before sunrise

- Maintaining the set temperature suitable for the crop, despite the unpredictability of sunlight

For example, a greenhouse of around 5 hectares consumes between 10 and 30 GWh per year (200 and 600 kWh/m²) of heat, depending on its production intensity, type of operation and location.

Today, these needs are mainly met by fossil fuels such as gas, propane and fuel oil through boilers and gas cogeneration systems that produce both heat and electricity. The cost of producing this heat is therefore subject to the volatility of the gas markets. This technical model has shaped the sector. It explains its current dependence.

Each crop has specific thermal requirements:

Tomatoes: 20 to 25°C (minimum 16°C)

Strawberries: 18 to 22°C (minimum 10°C)

Cucumbers: 22 to 28°C (minimum 18°C)

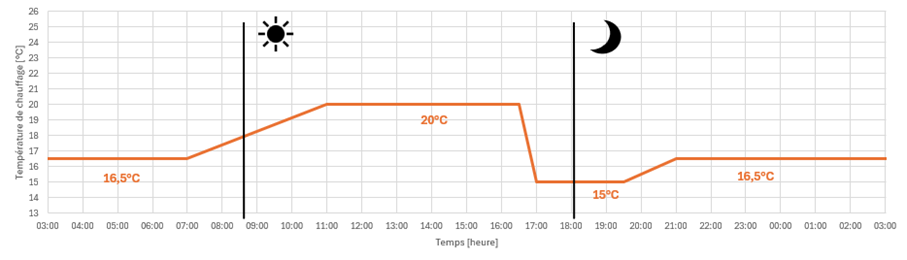

Depending on the time of day:

-

-

- In the morning, before sunrise, the farmer tries to remove moisture before heating.

- During the day, the heat is then maintained with more or less heating depending on the amount of sunshine and the outside temperature.

- At the end of the day, the plants are put to rest .

-

Example of temperature changes in a greenhouse over the course of a day

These temperatures must remain stable, even during periods of low sunlight. This requires an efficient, responsive and subtly controlled heating system.

Heat distribution in the greenhouse

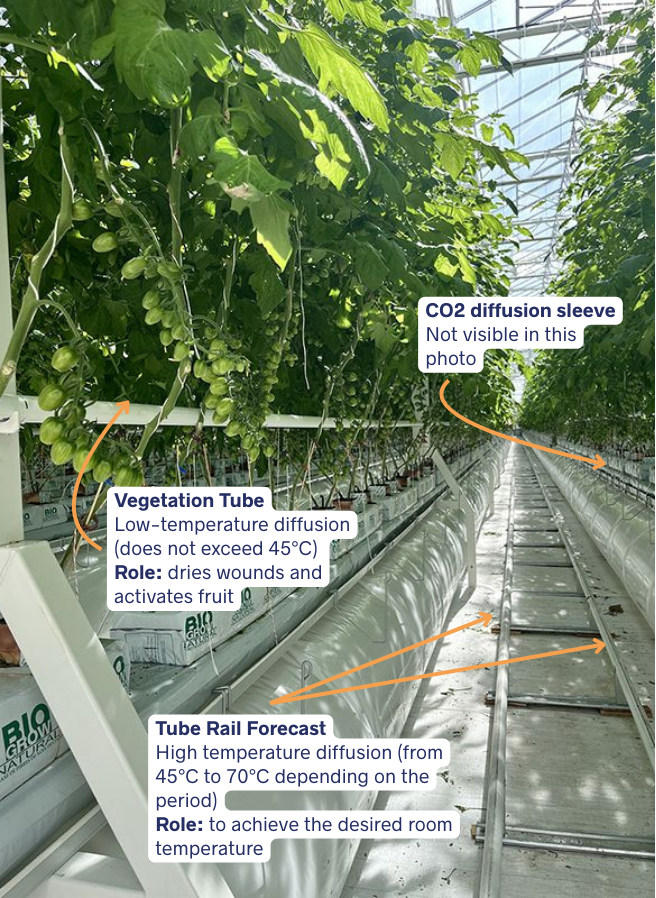

Greenhouse heating is generally based on two complementary networks:

-

-

- The low-temperature network (“vegetation pipes”) located as close to the plants as possible, operating at around 35°C (and never exceeding 45°C). It is used to maintain the growing conditions directly at the level of the crop.

- The high-temperature network (“forecast” or “rails”), which flows between 45°C and 70°C, is used to quickly raise the temperature or to cover more intense needs (night-time, low sunlight, peaks in demand, etc.).

-

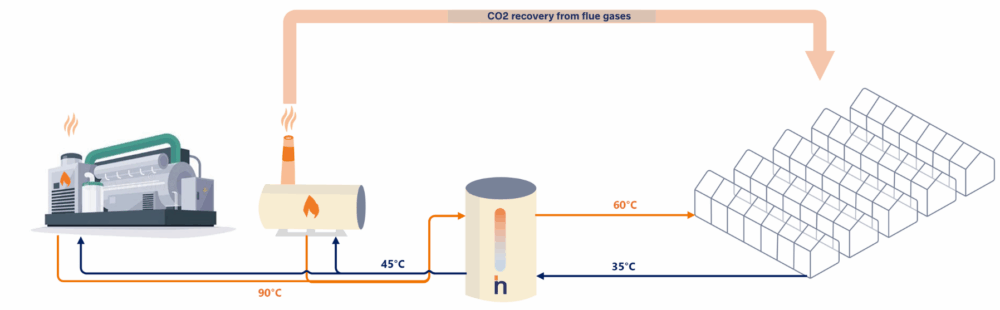

CO2: a production lever… when there is light

In addition to heat, greenhouses have a specific need for CO₂ consumption for photosynthesis.

CO₂ is therefore consumed at times when the greenhouse does not necessarily need heat.

This is why greenhouses are often already equipped with thermal storage (“open buffer”). This allows heat production and CO₂ consumption to be decoupled from the heat consumption (peaks, humidity, setpoint increases, etc.).

For a 5-hectare greenhouse, this requirement can reach from 1,500 to 2,000 tonnes of CO₂ per year, depending on the production targets. Historically, this CO₂ has come from the direct recovery of fumes realised by the gas boilers or has been purchased in liquid form.

This is a key point for the transition: replacing gas is not just about replacing heat. The heat/CO₂ balance needs to be rethought. Hence a key point for the transition: replacing gas is not just about replacing heat as a reduction in CO₂ can affect the greenhouse yields.

At Newheat, this balance between heat and CO₂ and the use of storage are integrated from the design stage onwards, to ensure both operational productivity and lower gas consumption.

Schematic diagram of existing heat generators on a farm

National challenges: towards more consistent agricultural heating

Greenhouses play an important role in French agricultural production, a sector directly affected by two national priorities: food sovereignty and energy independence.

A sector still massively reliant on fossil fuels

Heating weighs for around 50% of a greenhouse’s operating costs. Today, most French greenhouses still run on gas or propane. In 2021, nearly 80% of the heat consumed in France still came from gas.

This dependence weighs heavily on the production costs, increasing the vulnerability of farms to fluctuations in energy costs and international competition from countries that heat for a cheaper price or have more favourable climatic conditions.

Faced with rising gas prices and geopolitical uncertainties, reducing dependence on fossil fuels is becoming both a competitive advantage and an environmental goal.

This is where local renewable heat comes into its own: producing locally, with local energy.

Designing heating solutions tailored to market gardens

Meeting the specific needs of market-garden greenhouses requires to rethink the heat production around an integrated and controlled system.

A comprehensive approach

Newheat, a provider of decarbonation solutions, designs, develops, builds and operates multi-energy solutions for large heat consumers such as vegetable greenhouses.

Producing food locally, using local, stable and controlled energy, is the whole logic behind the energy transition of greenhouses.

Newheat follows this logic:

-

-

- Recovering waste heat from neighbouring industries,

- Developing solar thermal energy and heat pumps,

- Using electricity when it is competitive to produce heat (power-to-heat).

-

Newheat’s prioritisation of renewable heat technologies

Control, the key to performance

The supervision system developed by Newheat anticipates needs based on:

-

-

- Weather forecasts,

- Solar availability,

- The state of thermal storage,

- Production cycles,

- Energy prices (gas, electricity).

-

Thanks to this, we automatically activate the most efficient combination of producers to reduce costs and ensure continuity of heating.

The economic performance of a site does not depend on a single technology, but on how they are managed together, based on prices and actual needs.

Technical solutions for a smart energy mix

Every greenhouse is unique. Efficiency requires a balanced energy mix, where each technology plays a specific role:

| Technology | Principle | Key roles | Main challenges |

| Waste heat recovery | Recovery of waste heat (smoke, air, hot water) from neighbouring industrial processes | Local and competitive source, can be combined with thermal storage | Depends on the availability, quality and proximity of the waste heat source |

| Solar thermal | Hot water production via solar collectors | Sustainable technology (>30 years) and high efficiency Low OPEX and low electricity consumption |

Requires land for installation near the site Seasonal production (April–October) |

| Thermal storage | Daily hot water storage in an “Open Buffer” or inter-seasonal storage in a “PTES – Pit Thermal Energy Storage” | Storage of heat produced by all producers, allowing production to be shifted from consumption Inter-seasonal storage allows several months’ shift Enables management of production based on energy prices (Power-to-Heat) |

Cost and time required for grid connection Securing electricity supply Requires careful management to optimize market benefits Remuneration not guaranteed in the coming years |

| Electric boilers | Hot water production using electricity. These are integrated as backup and provide flexibility for the network | Total coverage possible, economic optimisation according to market mechanisms | Cost and time required for connection to the electricity grid. Securing the electricity supply. Requires careful management in order to make the most of market mechanisms. Associated remuneration not guaranteed in the coming years |

| Heat pumps |

Increases return temperature of greenhouse hot water networks through mechanical compression | Overall efficiency greater than 3 for this type of application | Control the coefficient of performance (COP) according to the source (air or waste heat). Securing the electricity supply. High maintenance costs and shorter service life |

These technologies are modular and complementary. They can be integrated into existing installations or new greenhouses.

The control system developed by Newheat adjusts production in real time to maintain the temperature in greenhouses while minimising costs.

The result: improved thermal stability, reduced gas consumption and controlled overall costs.

A concrete example: stabilising production and reducing dependence on gas

We support an 8-hectare conventional tomato production farm that is pesticide-free and HVE (High Environmental Value) certified.

The farm is heated by:

- Waste heat recovery from a nearby waste incinerator;

- A propane boiler: used in addition to the waste incinerator during maintenance and corrective shutdowns;

- The site also has a 3,000 m3 storage tank.

Although already exemplary, this reliable configuration remained sensitive to the incinerator shutdowns and fluctuations in the price of propane.

The solution implemented

The solar thermal plant supplies renewable heat to market gardens

The operator wanted to supplement its carbon-free heat production mix with a competitive and reliable renewable heat solution. The aim was to achieve a more stable and competitive heat cost for the site in the long term by reducing its propane consumption as much as possible in order to ensure the site’s activity.

With this in mind, we designed and built a turnkey solar thermal plant:

- Installation of a solar thermal plant,

- Coupling with 1,500 m³ storage,

- Implementation of smart energy management.

Expected performance

- 80% of needs covered by renewable sources,

- Propane consumption reduced by a factor of four,

- More stable greenhouse temperatures,

- Energy costs predictable over several years.

Newheat’s tailor-made control system coordinates all heat producers on site (solar heat, storage and other producers) according to the weather and actual demand from the greenhouses. It optimises heat production in order to maximise overall performance while meeting the specific needs of the site. This management system is linked to an operation and maintenance service with a performance guarantee, ensuring the reliability and sustainability of the solution.

In this way, the operation gains autonomy, stabilises operating costs and increases competitiveness, while reducing its carbon footprint.

We are delighted with the installation of this solar thermal plant by Newheat. It now allows us to heat our tomatoes with 98% renewable energy and to become more energy self-sufficient: an issue that is very important to us. It is another step towards creating an agricultural model for the future: a virtuous model that creates local jobs, uses neither fossil fuels nor pesticides, and has no impact on water resources. Our example shows that it is possible!

Geoffrey Goutoule, director of Les Tomates d’Auïtou

Towards a more autonomous and sustainable agriculture

Heat, often invisible, is at the heart of the greenhouse agricultural model. It sets yields, crop quality and economic viability.

By combining local renewable heat, storage and control, vegetable greenhouses can now secure their production, control their margins and become totally or partially independent of natural gas, while contributing to the energy transition. This gradual change is fully in line with the national trajectory of energy and agricultural sovereignty.

Newheat helps greenhouses for vegetables production to secure their production and margins through competitive, stable and controlled renewable heat, with or without investment, and without additional complexity, taking into account all the challenges facing farms, including CO₂.

Field of solar thermal collectors for heated market garden greenhouses Les Tomates d’Auitou

After reading this article, you are convinced of the benefits of renewable energy sources for supplying renewable heat to your market garden greenhouse and would like to explore these solutions in more detail?

Do not hesitate to contact us to discuss this further! here

Read our article on thermal storage.